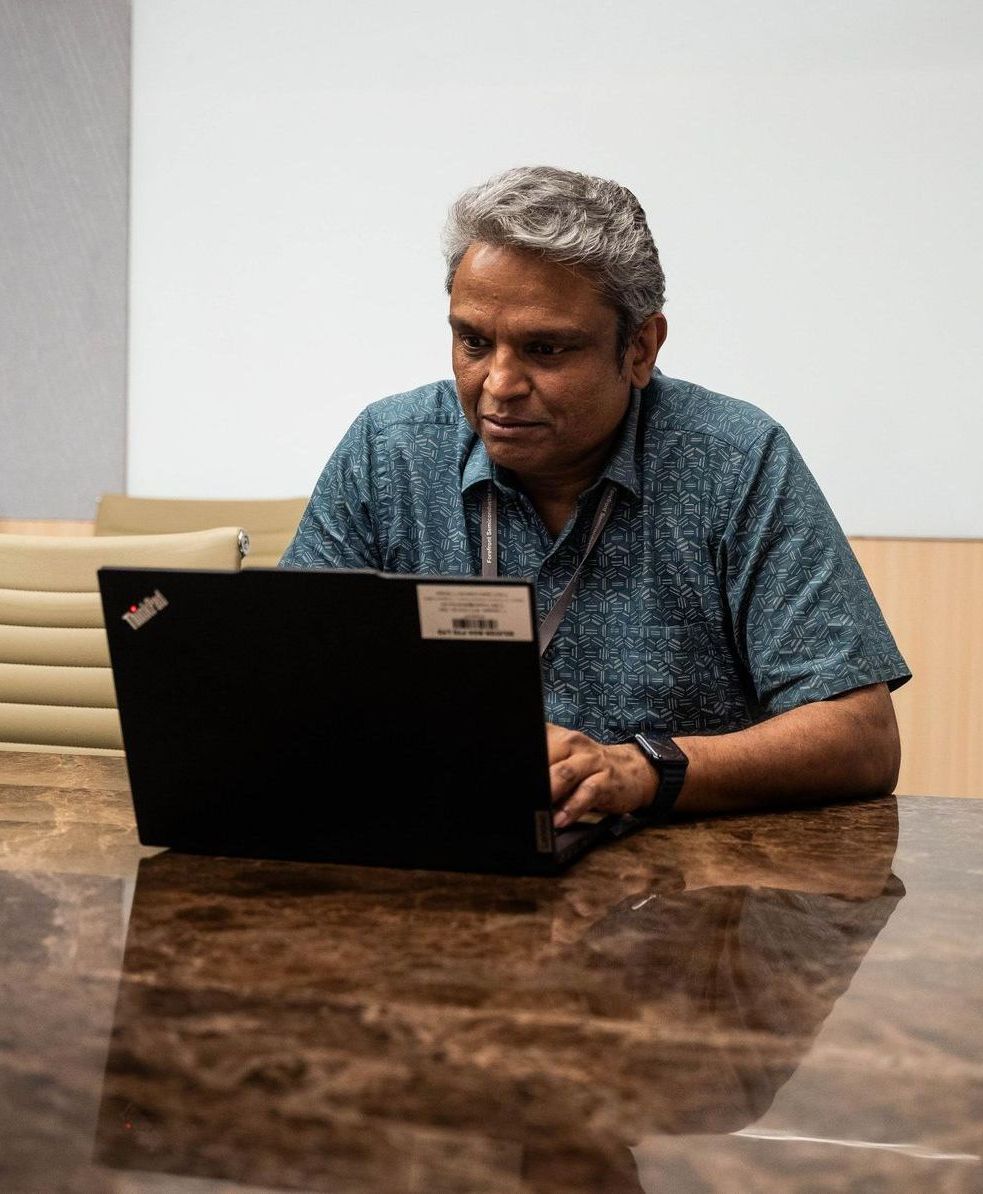

After working as an engineer in the electronics industry for over a decade, Anand, driven by his passion for improving processes and ensuring a safe work environment, decided to pivot and take up an opportunity with the Environmental, Health, and Safety (EHS) team. He has not looked back since.

Anand aims to be an EHS champion at Silicon Box, continuously optimizing the company's operational standards and employee well-being to fulfill its mission. Within a year of joining, he has helped Silicon Box achieve certifications in quality management (ISO 9001:2015), occupational health and safety management (ISO45001:2018), and environmental management systems (ISO14001:2015).

To mark the importance of International Day for Safety and Health at Work, we spotlight Anand, our EHS officer, as he shares insights on the ISO45001:2018 certification process and what his role entails.

Overview of the ISO 45001 Certification Process

What did the ISO 45001 certification process entail?

The ISO 45001 certification process was no small feat! In addition to writing policies, protocols, and license applications, we had to implement a series of routine meetings, training courses, and tests designed to mitigate health and safety risks. We created safety management systems from scratch, which included developing informational materials, conducting regular safety meetings, and establishing an internal audit routine to prepare our employees for emergencies.

We also had to ensure that relevant colleagues were certified in risk management by taking the bizSAFE Level 2 courses – a key requirement for our business. The uncertainty about covering all bases for the final audit certainly kept me awake at night, as obtaining certification for Silicon Box was of utmost importance to me.

What did you learn from the ISO 45001 certification process?

Change management can be achieved with the right approach.

One of the most significant challenges was not the certification process but fostering colleagues' understanding. Since we had the opportunity to build safety policies from the ground up, many team members with extensive experience in previous organizations were eager to share their best practices. To address this, we engaged with our colleagues to understand their concerns and effectively communicated the purpose and benefits of the selected protocols that would work for our company.

Gap analysis insights helped identify hurdles.

The insights gained from a gap analysis exercise were an essential aspect of the certification journey. We discovered that many employees required training and certifications from accredited providers due to Silicon Box's unique technological processes. Although organizing these courses was initially challenging due to competing business priorities, it became necessary to meet business demands as our production capacity increased.

Have contingency plans that are flexible to operational demands.

Reflecting on the entire certification journey, I learned the importance of enabling colleagues to fulfill their operational responsibilities while meeting certification requirements. Sometimes, urgent operational tasks take precedence over planned training sessions that we have already spent weeks preparing.

Moving forward, we realized that incorporating contingency training plans into our initial strategy would have been beneficial to balance operational needs with certification implementation.

Employee Engagement and Cultural Transformation

How did you involve your colleagues and motivate them to prioritize a robust, safe work environment?

Consistent communication was key to engaging employees in our mission to create a safer workplace. By enabling an environment of transparency and open dialogue, we encouraged staff to voice their concerns and contribute their ideas. This collaborative approach helped to build a culture that prioritized health and safety.

Make safety personal

We embraced an "Employee Safety First" philosophy that places individual well-being at the forefront of our priorities. We focused on identifying critical areas for improvement by asking essential questions: "Which safety protocols will most directly impact our employees?" and "What urgent actions need to be taken to ensure their safety?" Through this frame of thinking, we ensured all employees were familiar with evacuation procedures, followed by department-specific training needs. By centering efforts on enhancing employee safety first, a solid foundation was established for further improvements.

How would you describe the evolution of our safety culture since the beginning of the ISO 45001 journey?

Digital Transformation in Occupational Safety

What were some digital tools that aided the implementation of safety management?

Cloud-enabled services have greatly improved our safety management systems by streamlining processes, enhancing communication, and facilitating training. This has made it easier for my colleagues and I to engage with safety protocols.

For example, we have digitized daily work permit approvals and mandatory training to reduce physical paperwork and conserve workforce resources. To accommodate contractors in their required training, we increased accessibility and flexibility by converting our in-person Safety Induction Course (SIC) into a self-learning online module with an assessment quiz.

Additionally, we implemented an Electronic Permit-to-Work system that facilitates quicker approvals and allows managers to stay connected with our contractors. These digital transformations save our colleagues significant time and stress, enabling them to focus on more fulfilling tasks.

Advice to safety professionals planning to undertake the ISO ISO 45001 certification process

How has leading this certification process contributed to your professional growth?

Leading the certification process from start to finish was challenging but it was equally fulfilling, and I see it as an invaluable opportunity. I experienced a great sense of achievement, which boosted my confidence in accomplishing such a challenging task.

If you could restart the certification process, what would you do differently?

If circumstances allow, I will involve representatives from various departments right from the beginning to create a sense of ownership and ensure it is a team effort for continuity.

What advice would you give to safety professionals just beginning their ISO 45001 journey in this era of digitalization?

Using a digital platform in safety management helped reduce administrative tasks, making our work more engaging. We were able to collaborate with more colleagues on various initiatives to raise safety awareness. In addition, AI technology can to some degree help you understand the complexities of ISO certifications and monitor evolving legislative and regulatory requirements.

As for a Career at Silicon Box...

Why should people apply to work at Silicon Box or join your EHS team?

Silicon Box is a fantastic workplace if you are ready for a challenge and seeking a refreshing change in a unique work environment. I enjoy working here because of the people, and my manager provides substantial support.

I am looking for team members who share my passion and commitment to environmental, health, and safety initiatives. Safety is akin to an insurance policy—you may not realize how your efforts will someday impact someone's life. At the end of the day, I find fulfillment in knowing that I helped my company make a difference by raising awareness that environmental, health, and safety issues are just as crucial as profit margins.

#MomentToRemember

Since becoming an EHS officer, I have conducted numerous training sessions, including a workshop on first aid for small children. One day, a colleague called to thank me because the knowledge from my workshop helped save her niece. Hearing this impacted me. It reminded me that even though the routine efforts may not receive immediate feedback, I can make a difference.

Are you looking forward to work with passionate and motivated colleagues like Anand?

Reach out to us for career opportunities at hr@silicon-box.com or explore our

Job Portal.